IceNein

Reduce energy and diesel use, improve product temperature stability, and reduce emissions for refrigerated trailers

What is IceNein

IceNein is a coating applied to heat exchangers in HVAC-R systems that reduces frost and ice growth on heat exchanger surfaces.

We have developed coatings for refrigeration evaporators that reduce the impact of ice on day-to-day operations.

Our coatings use a unique mechanism to remove droplets from a surface before they can freeze.

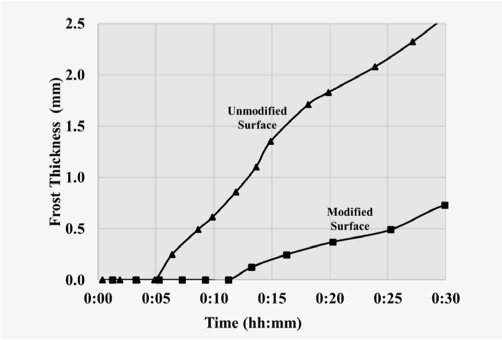

Third party tests have shown that IceNein™ coatings reduce the ice formation rate by 60%, reduce the defrost duration by 40%, and minimize entrained water in evaporator heat exchangers.

IceNein Benefits for TRU Operators

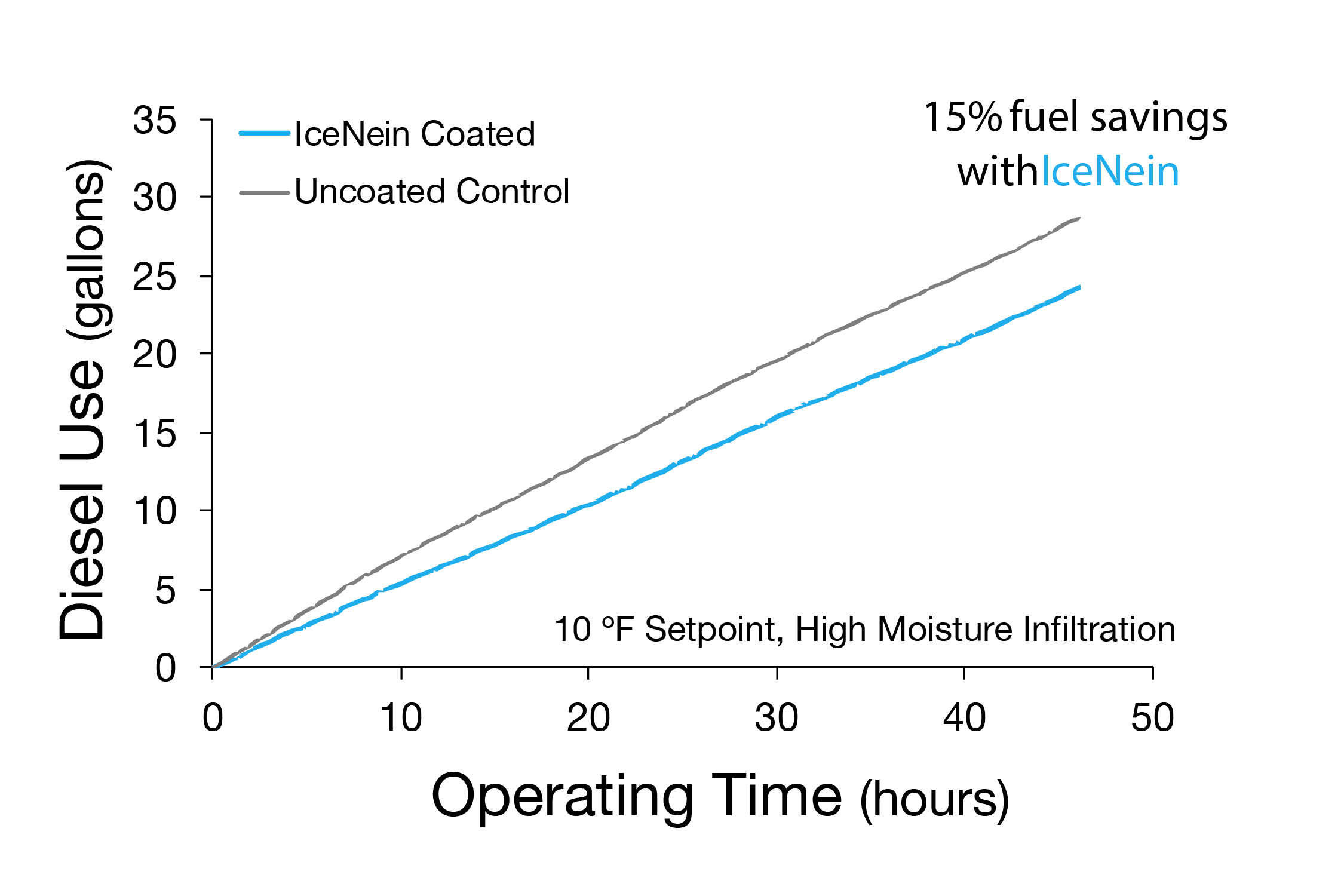

Icing on the evaporator reduces system operating efficiency, and frequent defrosts also release heat into the trailer that must subsequently be removed after each cycle, increasing diesel use.

Diesel and Energy Savings

Our product directly address these icing problems and can reduce diesel consumption by about 10% under typical operating conditions.

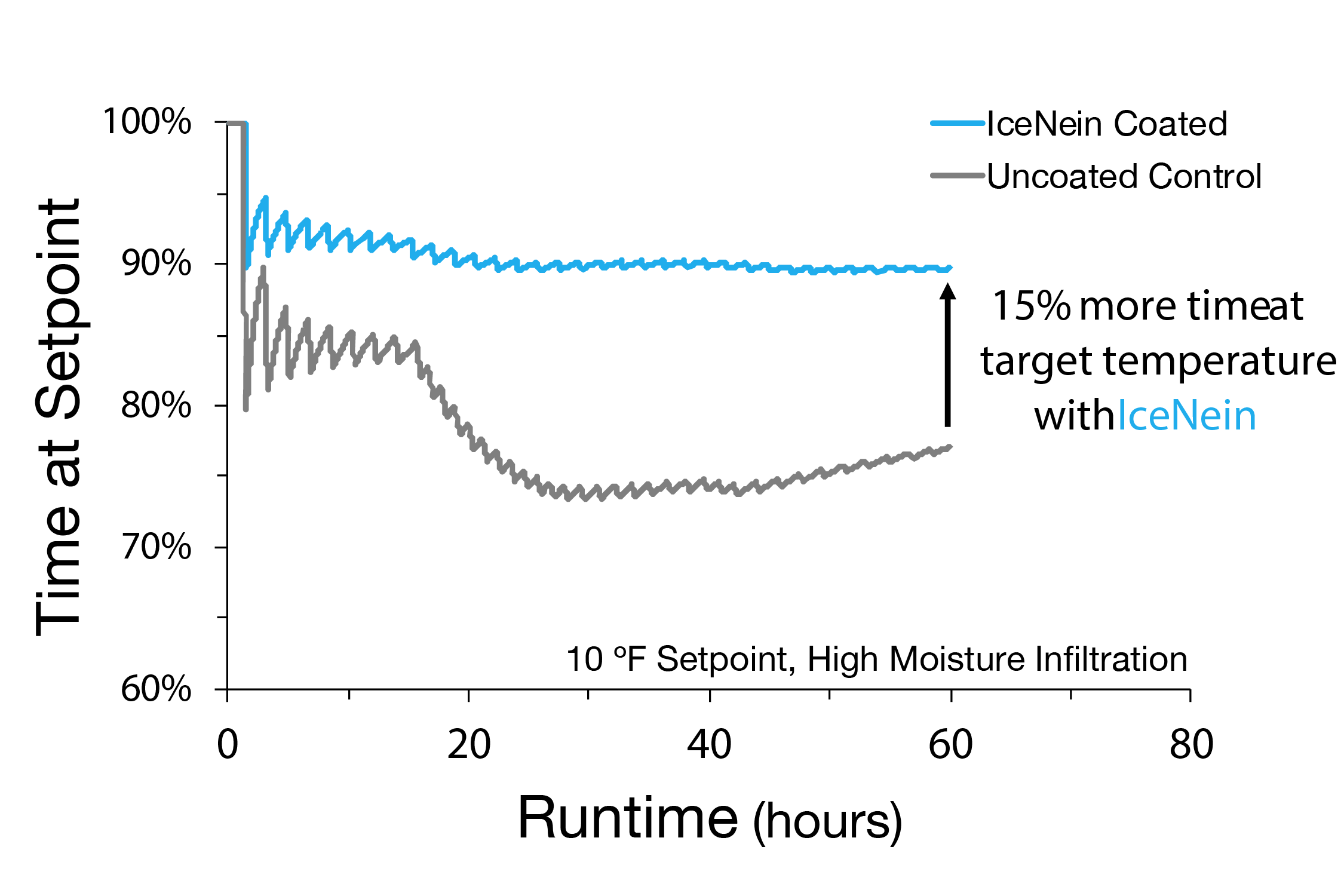

Cargo Temperature Stability

During the defrosting of iced evaporators, the TRU stops cooling the cargo and releases a large amount of heat into the trailer - this causes frequent temperature swings in the trailer that can lead to food and drug spoilage or a lapse in temperature compliance.

Our product directly reduces the duration and frequency of defrost cycles, resulting in about 60% less cooling downtime and improved cargo temperature stability.

Longer Equipment Life

Frequent defrosting requires longer cooling cycles that increase operating hours and wear-and-tear on the engine and compressor - this can increase operating costs, increase maintenance frequency and reduce equipment lifetime.

Our product allows the engine and compressor to operate less frequently and at lower speeds, potentially increasing useful equipment life and reducing engine maintenance frequency by about 10% to 15%.

Carbon and Pollutant Reduction

Icing of the evaporator reduces system operating efficiency and increases diesel consumption, carbon emissions, and pollutants such as NOx. Governments are fining operators for these emissions, increasing operating expenses.